Setting up Preventative Maintenance for Locations

Purpose Statement

The purpose of this article is to demonstrate how to set up Preventative Maintenance (PM) for Locations. Preventative Maintenance automates recurring work orders to support station and facility upkeep using time-based and/or trigger-based schedules.

Background Information

Preventative Maintenance for Locations automatically generates work orders using:

A scheduled timeframe (date-based cadence)

A triggering event (when available in your configuration)

An optional OR condition to trigger on whichever occurs first

Common use cases include station inspections, alarm system checks, generator testing, HVAC filter changes, and recurring facility maintenance tasks.

Prerequisites:

Location records exist in Assets

Work Order Boards and Work Order Types are configured

Required Permissions

To complete this process, users typically need:

Assets: Setup (view/edit)

Preventative Maintenance: Create/Edit

Work Orders: View (Create/Edit recommended)

These permissions are typically assigned to admin, data-manager, or supervisor roles.

Video

Step-by-Step Guide

Step 1: Access Preventative Maintenance

There are two places to add Preventative Maintenance (PM) for Locations:

Step 2: Add a New Maintenance Schedule

- From either of the entry points above, click Add Maintenance (as shown above).

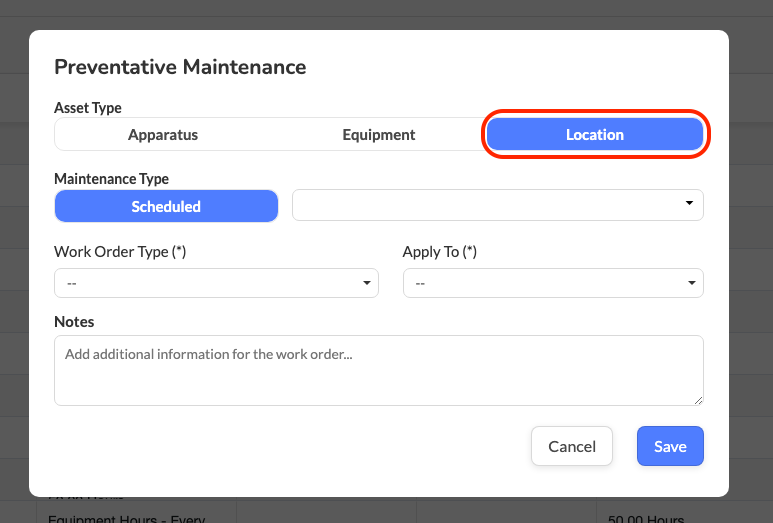

Step 3: Select the Locations Tab

- In the Add Maintenance window, select the Locations tab.

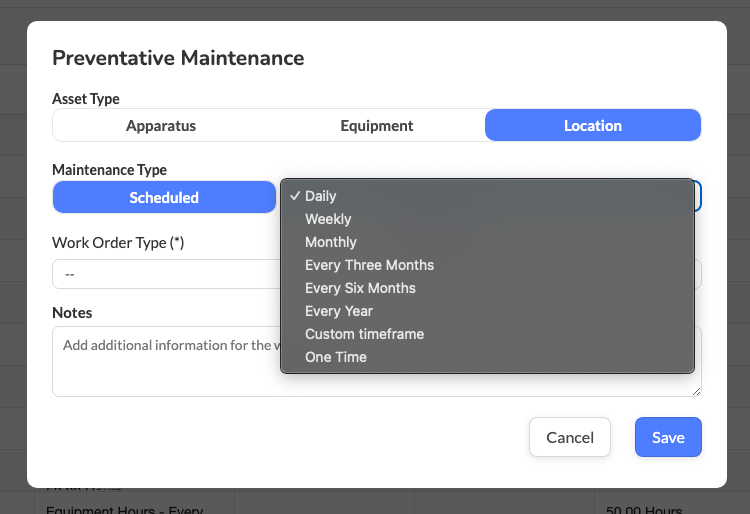

Step 4: Choose How the PM Will Trigger

Preventative Maintenance work orders for Locations can only be set to Scheduled (a time-based cadence).

Step 7: Select the Work Order Type

In the Work Order dropdown, select the work order type that should be generated.

Step 8: Select the Location(s)

In the Location selector, choose the station/location(s) this PM should apply to.

Step 9: Save the Preventative Maintenance

Click Save.

The PM will now automatically generate work orders based on your configured schedule (for example: every quarter, every month, or a combined condition if enabled).

Best Practices

Use scheduled PMs for inspections, compliance checks, and recurring facility routines

Standardize Work Order Types for facility maintenance reporting

Review location PM schedules annually or after major station projects

Avoid duplicating PM schedules for the same location unless intentionally layered

Troubleshooting & FAQs

I don’t see a triggered option for Locations. Is something wrong?

Not necessarily. Some accounts only support scheduled PMs for Locations. Use timeframe-based scheduling.

PM isn’t generating a work order. What should I check?

Confirm the PM was saved successfully

Verify the condition values are valid

Ensure a Work Order Type is selected

Confirm the location is selected and active

Can I apply one PM to multiple locations?

Yes. You can select multiple locations in Step 8.

Related Articles

Setting up Preventative Maintenance for Locations

Purpose Statement The purpose of this article is to demonstrate how to set up Preventative Maintenance (PM) for Locations. Preventative Maintenance automates recurring work orders to support station and facility upkeep using time-based and/or ...Setting up Preventative Maintenance for Equipment

Purpose The purpose of this article is to demonstrate how to setup Preventative Maintenance for Equipment. Related Articles How to Change Preventative Maintenance Cycles for Individual Apparatus, Items of Equipment, and Stations Managing Preventative ...Setting up Preventative Maintenance for Equipment

Purpose Statement The purpose of this article is to demonstrate how to set up Preventative Maintenance (PM) for Equipment. Preventative Maintenance automates recurring work orders based on time and/or usage to improve readiness, reduce failures, and ...Setting up Preventative Maintenance for Equipment

Purpose Statement The purpose of this article is to demonstrate how to set up Preventative Maintenance (PM) for Equipment. Preventative Maintenance automates recurring work orders based on time and/or usage to improve readiness, reduce failures, and ...Setting up Preventative Maintenance for Apparatus

Purpose Statement The purpose of this article is to demonstrate how to set up Preventative Maintenance (PM) for Apparatus. Preventative Maintenance automates recurring work orders based on time and/or usage to keep fleet vehicles service-ready and ...